Commercial air doors are specialized entrance solutions for food processing areas, offering climate control and preventing contaminated air entry. They enhance efficiency, energy savings, and hygiene, with advanced technology and customizable features like heated air and warehouse door heating. Proper installation, regular maintenance, and adherence to industry standards ensure optimal performance, safety, and sustainability in food processing facilities.

“Sanitary commercial air doors are indispensable in food processing areas, ensuring optimal hygiene and efficiency. This article explores the intricate world of these specialized doors, offering a comprehensive guide for industry professionals. From understanding their unique design to uncovering key benefits, we delve into the essential features that set them apart. Additionally, we provide practical insights on installation, maintenance, and navigating regulatory compliance. Discover how commercial air doors revolutionize food safety protocols.”

- Understanding Sanitary Commercial Air Doors

- Key Features and Benefits for Food Processing

- Installation and Maintenance Best Practices

- Regulatory Compliance and Industry Standards

Understanding Sanitary Commercial Air Doors

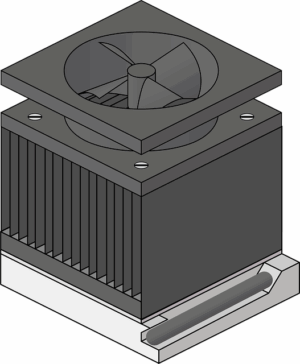

Sanitary commercial air doors are specialized entrance air barriers designed to maintain hygiene and efficiency in food processing areas. These doors operate as climate control doors, heated air doors, or HVAC air curtains, effectively preventing contaminated air from entering clean zones. They serve as crucial industrial entrance solutions for warehouses, retail spaces, and other facilities where temperature-controlled environments are essential.

Commercial door systems equipped with advanced technology ensure optimal performance while promoting energy efficiency. By utilizing innovative designs, these doors can withstand harsh conditions, providing reliable protection against unwanted elements and maintaining the desired climate within. Whether it’s a bustling warehouse or a pristine food processing facility, sanitary commercial air doors offer versatile solutions tailored to specific needs.

Key Features and Benefits for Food Processing

Commercial air doors have emerged as indispensable components in food processing areas, offering a multitude of benefits that extend beyond basic entry control. These advanced entrance air barriers are meticulously designed to maintain optimal climate conditions, ensuring product quality and safety throughout manufacturing processes. By implementing energy-efficient barriers like commercial air doors, food processing facilities can achieve significant cost savings through reduced energy consumption, making them an essential part of any modern, efficient operation.

Moreover, these innovative door systems incorporate features such as heated air doors and warehouse door heating to combat the challenges posed by varying environmental conditions. They act as robust HVAC air curtains, effectively preventing contaminated air from entering clean zones, thereby minimizing cross-contamination risks. Such industrial entrance solutions not only contribute to maintaining a sterile environment but also enhance overall operational efficiency, making them crucial components in the food processing landscape.

Installation and Maintenance Best Practices

Proper installation and regular maintenance are key to ensuring that commercial air doors function effectively in food processing areas. When installing these entrance air barriers, it’s crucial to follow manufacturer guidelines and industry standards to create a seamless fit around door frames, preventing any gaps that could compromise the barrier’s integrity. This includes using high-quality seals and gaskets to maintain positive pressure, which is essential for keeping contaminants out and maintaining optimal climate control.

Maintenance practices should include regular cleaning of the doors and sensors, as well as checks for wear and tear on components like hinges and actuators. Industrial entrance solutions like commercial door systems and heated air doors require specific care to ensure they operate efficiently year-round, contributing to energy savings and overall environmental control. Timely maintenance also extends the lifespan of these advanced commercial entrance technology products, making them a more sustainable investment for food processing facilities.

Regulatory Compliance and Industry Standards

In the food processing industry, maintaining strict hygiene and safety standards is non-negotiable. Regulatory Compliance and Industry Standards play a pivotal role in ensuring that commercial air doors used in these areas meet specific criteria to prevent contamination. These regulations govern everything from material composition to installation practices, aiming to create a robust barrier against airborne contaminants. For instance, the U.S. Food and Drug Administration (FDA) sets guidelines for food-contact surfaces, while international standards like ISO 22000 provide a framework for HACCP (Hazard Analysis and Critical Control Points) plans.

Commercial air doors, including entrance air barriers, heated air doors, and HVAC air curtains, are essential components of industrial entrance solutions and retail air barriers. They not only facilitate controlled climate control but also significantly enhance energy efficiency in warehouses and other large facilities. When selecting these commercial door systems, it’s crucial to choose products that meet industry standards for safety and performance. High-quality options include energy-efficient barriers designed to reduce utility costs while maintaining optimal temperature and humidity levels, ensuring a seamless yet hygienic flow of people and goods within food processing areas.

Sanitary commercial air doors are indispensable for maintaining hygiene and efficiency in food processing areas. By understanding their key features, implementing best installation and maintenance practices, and ensuring regulatory compliance, businesses can maximize the benefits these doors offer. Commercial air doors play a vital role in creating a cleanroom environment, minimizing cross-contamination, and enhancing overall process reliability, making them a game-changer for the industry.